School

Nova College

WSA section

Curriculum, Didactics, Environment & Professionalization

Good Practice

Smart Maintenance master class and elective courses

The Techport companies and the Province of North Holland had several questions about circular entrepreneurship, smart industry and digitalization. This led to a partnership with Nova College in which a Smart Maintenance master class and Smart Maintenance optional courses for Level 3 and Level 4 were developed together. With each other means that the participating companies and education develop the lessons together and that these companies all contribute during the teaching series in the form of guest lectures or workshops. In addition, the other technical courses are enriched with knowledge and assignments in the field of Smart Maintenance.

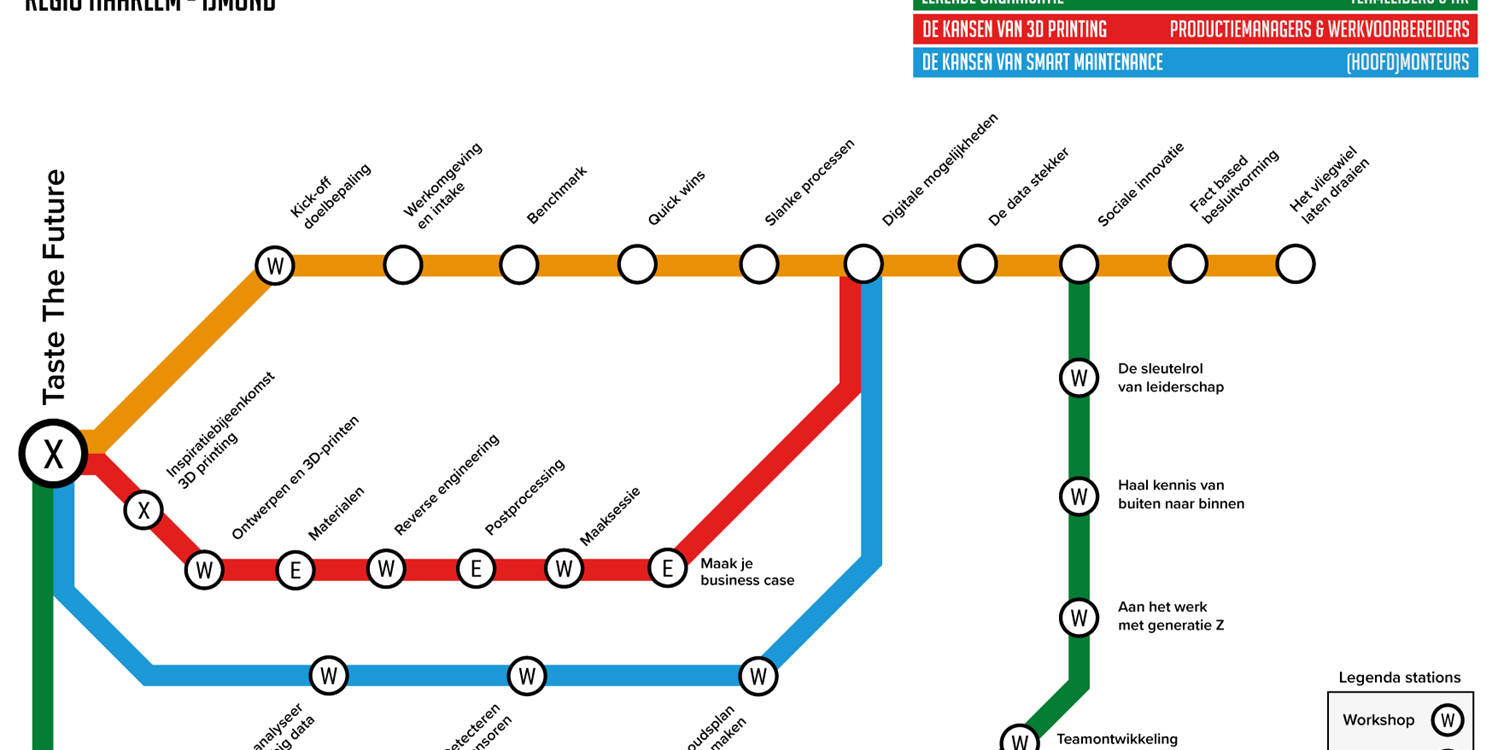

Then there was added to that: the Smart Maintenance Metroline, to also introduce the non-Techport manufacturing companies to the topic of Smart Maintenance. The Metroline is series of workshops with innovative topics including Smart Maintenance.

Smart Maintenance is about smart maintenance. This starts with placing sensors on machines to collect data about the operation of these machines. By analyzing this data, predictions can be made about when a certain type of maintenance should take place. Performing maintenance at the right time ensures that less waste is produced since the parts that are still good are not simply replaced because it is the time to do so. For example, after a certain number of revolutions or after a predetermined number of products have been made. By applying smart maintenance, a part is only replaced when there is significant wear which means that such a part is actually due for replacement.

By applying data analysis, it is also possible to choose to carry out maintenance in the production line at several locations simultaneously during downtime. This avoids having to stop the production process multiple times for maintenance and also restart it. Less frequent restarts also in turn lead to savings in energy costs and a reduction in CO2 emissions, respectively.

But there is also a human factor to Smart Maintenance. This type of maintenance ensures that the number of failures is reduced, which also prevents a lot of annoyance for the process operators and mechanics. Less annoyance usually also means less stress and this in turn leads to more job satisfaction so that people can continue to do this work for longer. By giving process operators and mechanics extra training on the subject of Smart Maintenance, they are also up to date in knowledge and skills so that they can continue to do their work for years to come because they can keep up with all the changes in circular entrepreneurship, smart industry and digitalization.

With this master class and the elective courses, teachers and workplace supervisors are prepared through a number of "train the trainer" sessions. This allows them to better supervise the students following this elective course because they know the main features of the program and what kind of assignments the students have to perform. All training sessions both to teachers, practical supervisors and students are carried out with some regularity in the Fieldlab Smart Maintenance.

You can find all attachments to the good practice on the SustainaBul MBO website!

Stay tuned!

Smart Maintenance at Nova College is one of the good practices of the SustainaBul MBO. Do you also want to take sustainable steps at your school? Join the SustainaBul MBO network via the website or contact project manager Roos Wemmenhove. Stay informed about learning for sustainable development in the mbo? Subscribe to the network MBO for Tomorrow!